- Standard: GOST 9389-75, EN 10270-1, DIN 17223, DSTU ISO 8458-2

- Diameter: from 0,30 mm up to 8,0 mm

- Application: for the production of springs coiled in a cold condition and not subjected to hardening.

GOST 9389 – 75

GOST 9389 – 75

Acc to mechanical properties the wire is produced:

- grades В, V;

- class 1, 2, 3;

Acc to the precision of production:

- normal precision;

- higher precision.

EN 10270-1

Acc to mechanical properties the wire is produced

- group SL, SM и SH;

Acc to the type of coating:

- without coating;

- phosphate coating;

- galvanized.

DIN 17223

Acc to mechanical properties the wire is produced:

- grade А, grade В;

Acc to the type of coating:

- without coating;

- phosphate coating;

MECHANICAL PROPERTIES OF WIRE according to GOST 9389-75, defining a class of wire:

| Diameter, mm | Tensile strength, N/mm2 | ||

| class 1 | class 2 | class 3 | |

| 0,30 | 2700 – 3040 | 2260 – 2700 | 1770 – 2260 |

| 0,32 – 0,36 | 2650 – 2990 | 2210 – 2650 | 1720 – 2210 |

| 0,40 – 0,60 | 2600 – 2940 | 2160 – 2600 | 1670 – 2160 |

| 0,63 – 0,80 | 2550 – 2890 | 2160 – 2550 | 1670 – 2160 |

| 0,90 | 2500 – 2790 | 2110 – 2500 | 1620 – 2110 |

| 1,00 | 2450 – 2740 | 2060 – 2450 | 1570 – 2060 |

| 1,10 | 2400 – 2700 | 2010 – 2450 | 1520 – 2010 |

| 1,20 | 2350 – 2650 | 1960 – 2350 | 1520 – 1960 |

| 1,30 | 2300 – 2600 | 1960 – 2300 | 1520 – 1960 |

| 1,40 | 2260 – 2550 | 1960 – 2260 | 1470 – 1960 |

| 1,50 | 2210 – 2500 | 1860 – 2210 | 1420 – 1860 |

| 1,60 | 2160 – 2450 | 1860 – 2160 | 1420 – 1860 |

| 1,70 – 1,80 | 2060 – 2350 | 1770 – 2060 | 1370 – 1770 |

| 1,90 | 2010 – 2300 | 1770 – 2010 | 1370 – 1770 |

| 2,00 | 2010 – 2260 | 1770 – 2010 | 1370 – 1770 |

| 2,10 | 1960 – 2210 | 1720 – 1960 | 1370 – 1720 |

| 2,20 – 2,30 | 1910 – 2160 | 1670 – 1910 | 1320 – 1670 |

| 2,50 | 1810 – 2060 | 1620 – 1860 | 1270 – 1620 |

| 2,80 | 1770 – 2010 | 1620 – 1860 | 1270 – 1620 |

| 3,00 | 1720 – 1960 | 1620 – 1860 | 1270 – 1620 |

| 3,20 | 1720 – 1960 | 1520 – 1770 | 1230 – 1520 |

| 3,50-3,60 | 1670 – 1910 | 1520 – 1770 | 1230 – 1520 |

| 4,00 | 1620 – 1860 | 1470 – 1720 | 1180 – 1470 |

| 4,20 | 1570 – 1810 | 1420 – 1670 | 1130 – 1420 |

| 4,50 | 1520 – 1770 | 1370 – 1620 | 1130 – 1370 |

| 5,00 | 1470 – 1720 | 1370 – 1620 | 1130 – 1370 |

| 6,00 | 1470 – 1720 | 1320 – 1570 | – |

| 7,00 – 8,00 | – | 1230 – 1420 | – |

At the request of the consumer, the supply of wire of intermediate diameters is allowed

MECHANICAL PROPERTIES OF WIRE according to ГОСТ 9389-75, defining a class of wire:

| Diameter, mm | Tolerance on tensile strength of wire in a lot, max, N/mm2, max | |||

| grade «B» | grade «V» | |||

| class 1, 2, 2А, 3 | class 1 | class 2, 2А | class 3 | |

| 0,30 – 0,40 | 280 | 340 | 440 | 490 |

| 0,45 – 0,56 | 260 | 340 | 440 | 490 |

| 0,60 – 0,70 | 240 | 340 | 440 | 490 |

| 0,80 – 0,90 | 230 | 340 | 440 | 490 |

| 1,00 – 1,10 | 220 | 290 | 390 | 490 |

| 1,20 – 1,30 | 210 | 290 | 390 | 440 |

| 1,40 – 1,60 | 200 | 290 | 290 | 440 |

| 1,70 – 1,90 | 200 | 290 | 250 | 390 |

| 2,00 – 3,00 | 200 | 250 | 250 | 340 |

| 3,10 – 6,00 | 200 | 250 | 250 | 290 |

| 7,00 – 8,00 | 200 | – | 200 | 200 |

MECHANICAL PROPERTIES OF WIRE according to EN 10270-1 (DIN 17223)

| Diameter, mm | Tensile strength, (Rm) N/mm2 | ||

| group SL (grade А) | group SM (grade V) | group SH | |

| 0,30 | 2370 – 2650 | 2660 – 2940 | |

| 0,3 < d ≤ 0,32 | 2350 – 2630 | 2640 – 2920 | |

| 0,32 < d ≤ 0,34 | 2330 – 2600 | 2610 – 2890 | |

| 0,34 < d ≤ 0,36 | 2310 – 2580 | 2590 – 2870 | |

| 0,36 < d ≤ 0,38 | 2290 – 2560 | 2570 – 2850 | |

| 0,38 < d ≤ 0,40 | 2270 – 2550 | 2560 – 2830 | |

| 0,40 < d ≤ 0,43 | 2250 – 2520 | 2530 – 2800 | |

| 0,43 < d ≤ 0,45 | 2240 – 2500 | 2510 – 2780 | |

| 0,48 < d ≤ 0,48 | 2220 – 2480 | 2490 – 2760 | |

| 0,48 < d ≤ 0,50 | 2200 – 2470 | 2480 – 2740 | |

| 0,50 < d ≤ 0,53 | 2180 – 2450 | 2460 – 2720 | |

| 0,53 < d ≤ 0,56 | 2170 – 2430 | 2440 – 2700 | |

| 0,58 < d ≤ 0,60 | 2140 – 2400 | 2410 – 2670 | |

| 0,60 < d ≤ 0,63 | 2130 – 2380 | 2390 – 2650 | |

| 0,63 < d ≤ 0,65 | 2120 – 2370 | 2380 – 2640 | |

| 0,65 < d ≤ 0,70 | 2090 – 2350 | 2360 – 2610 | |

| 0,70 < d ≤ 0,75 | 2070 – 2320 | 2330 – 2580 | |

| 0,75 < d ≤ 0,80 | 2050 – 2300 | 2310 – 2560 | |

| 0,80 < d ≤ 0,85 | 2030 – 2280 | 2290 – 2530 | |

| 0,85 < d ≤ 0,90 | 2010 – 2260 | 2270 – 2510 | |

| 0,90 < d ≤ 0,95 | 2000 – 2240 | 2250 – 2490 | |

| 0,95 < d ≤ 1,00 | 1720 – 1970 | 1980 – 2220 | 2230 – 2470 |

| 1,00 < d ≤ 1,05 | 1710 – 1950 | 1960 – 2200 | 2210 – 2450 |

| 1,05 < d ≤ 1,10 | 1690 – 1940 | 1950 – 2190 | 2200 – 2430 |

| 1,10 < d ≤ 1,20 | 1670 – 1910 | 1920 – 2160 | 2170 – 2400 |

| 1,20 < d ≤ 1,25 | 1660 – 1900 | 1910 – 2140 | 2150 – 2380 |

| 1,25 < d ≤ 1,30 | 1640 – 1890 | 1900 – 2130 | 2140 – 2370 |

| 1,30 < d ≤ 1,40 | 1620 – 1860 | 1870 – 2100 | 2110 – 2340 |

| 1,40 < d ≤ 1,50 | 1600 – 1840 | 1850 – 2080 | 2090 – 2310 |

| 1,50 < d ≤ 1,60 | 1590 – 1820 | 1830 – 2050 | 2060 – 2290 |

| 1,60 < d ≤ 1,70 | 1570 – 1800 | 1810 – 2030 | 2040 – 2260 |

| 1,70 < d ≤ 1,80 | 1550 – 1780 | 1790 – 2010 | 2020 – 2240 |

| 1,80 < d ≤ 1,90 | 1540 – 1760 | 1770 – 1990 | 2000 – 2220 |

| 1,90 < d ≤ 2,00 | 1520 – 1750 | 1760 – 1970 | 1980 – 2200 |

| 2,00 < d ≤ 2,10 | 1510 – 1730 | 1740 – 1960 | 1970 – 2180 |

| 2,10 < d ≤ 2,25 | 1490 – 1710 | 1720 – 1930 | 1940 – 2150 |

| 2,25 < d ≤ 2,40 | 1470 – 1690 | 1700 – 1910 | 1920 – 2130 |

| 2,40 < d ≤ 2,50 | 1460 – 1680 | 1690 – 1890 | 1900 – 2110 |

| 2,50 < d ≤ 2,60 | 1450 – 1660 | 1670 – 1880 | 1890 – 2100 |

| 2,60 < d ≤ 2,80 | 1420 – 1640 | 1650 – 1850 | 1860 – 2070 |

| 2,80 < d ≤ 3,00 | 1410 – 1620 | 1630 – 1830 | 1840 – 2040 |

| 3,00 < d ≤ 3,20 | 1390 – 1600 | 1610 – 1810 | 1820 – 2020 |

| 3,20 < d ≤ 3,40 | 1370 – 1580 | 1590 – 1780 | 1790 – 1990 |

| 3,40 < d ≤ 3,60 | 1350 – 1560 | 1570 – 1760 | 1770 – 1970 |

| 3,60 < d ≤ 3,80 | 1340 – 1740 | 1550 – 1740 | 1750 – 1950 |

| 3,80 < d ≤ 4,00 | 1320 – 1520 | 1530 – 1730 | 1740 – 1930 |

| 4,00 < d ≤ 4,25 | 1310 – 1500 | 1510 – 1700 | – |

| 4,25 < d ≤ 4,50 | 1290 – 1490 | 1500 – 1680 | – |

| 4,50 < d ≤ 4,75 | 1270 – 1470 | 1480 – 1670 | – |

| 4,75 < d ≤ 5,00 | 1260 – 1450 | 1460 – 1650 | – |

| 6,00 | – | 1400 – 1580 | 1590 – 1770 |

| 7,00 | – | 1350 – 1530 | – |

| 8,00 | – | 1290 – 1460 | – |

RECOMMENDATIONS

Before use the wire must be stored in dry, ventilated rooms with low humidity and without sudden changes in temperature to prevent rusting due to moisture condensation.

Before unwinding the wire in the coils, you must first release the coil from the bindings. This must be done carefully, especially when removing the end of the knitting wire threaded through a coil to prevent pulling out and entangling the turns of wire.

Then release the upper end of the wire threaded through the upper turns around the entire circumference of the coil. Before installing and threading the wire into the machine, make sure that the wire is not interwoven with adjacent turns. To do this, it is necessary to lift the end and several turns of wire and then put one turn back into the coil, making sure that there is no “overlapping” of the turns. This will prevent entanglement and wire breakage during the unwinding process.

Before unwinding coils of Z-2 or coils of another type, it is necessary to assemble the coils into a special detachable reel or other unwinding device, tightly fix the cheeks of the coil, ensuring maximum pressure against the wire to prevent “tightening” of the wire between the coils and the cheek of the unwinding device, which can lead to a break wire during unwinding and only after that release the coil from packing metal tapes. After that, tighten the coil or other device again for maximum clamping of the wire coil. Find and free the end of the wire, making sure that there is no “overlap” of the wire through adjacent turns. This will eliminate wire breaks during unwinding.

Each spool is wrapped with waxed paper, which is attached with twine; packed spools are stacked on a wooden pallet measuring (1070x815) mm. When packing the spools, the pallet is pre-lined with plastic wrap, a sheet of cardboard and a cardboard layer is laid between each row of spools. The spools laid out on a pallet are tied with a metal tape (0.5x16) mm, covered with a plastic film on top and wrapped with “stretch” film.

- Type of winding:Spools BS-60

- Dimensions, mm, d*D*h:118х255х152

- Weight kg:16 - 30

- Diameter range, mm:0,3 – 0,55

- Type of winding:Spools BP-60S

- Dimensions, mm, d*D*h:118х255х152

- Weight kg:16 - 25

- Diameter range, mm:0,3 – 0,55

The coils are tied with the same wire or heat-treated wire Ø 0.8 mm. The coils are stacked in wooden boxes with a size of (1100 * 880 * 715) mm for a package of 1000 kg and a size of (1100 * 880 * 550) mm for a package of 500 kg. Boxes are pre-lined with plastic wrap. At the request of the consumer, each coil of wire must be packed in waxed paper and each row of coils is laid with corrugated cardboard.

- Type of winding:Coil

- Dimensions, mm, d*D*h:140х240х70

- Weight kg:7 – 14

- Diameter range, mm:0,3 – 0,55

Each coill is tied with a heat-treated wire of Ø1.8 mm in at least four places evenly spaced around the coil. Coil without coating is lubricated with industrial oil, galvanized wire is not lubricated. Each coil is packed in a polypropylene cloth, packaged (4 - 5 coils) with a 0.5 x 16 mm metal steel tape in four places evenly spaced around the bag circumference. The tapes are fixed with heat-treated wire Ø1.8 mm around the circumference of the middle of the package.

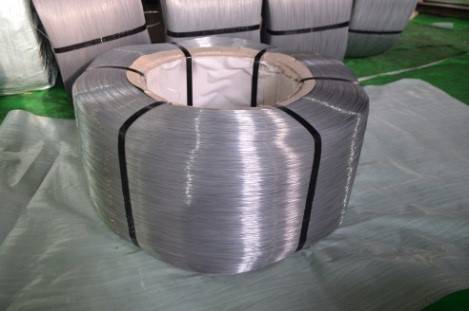

- Type of winding:Coil

- Dimensions, mm, d*D*h:220х400х160

- Weight kg:60 - 100

- Diameter range, mm:0,6 – 1,3

Each coill is tied with a heat-treated wire of Ø1.8 mm in at least four places evenly spaced around the coil. Coil without coating is lubricated with industrial oil, galvanized wire is not lubricated. Each coil is packed in a polypropylene cloth, packaged (4 - 5 coils) with a 0.5 x 16 mm metal steel tape in four places evenly spaced around the bag circumference. The tapes are fixed with heat-treated wire Ø1.8 mm around the circumference of the middle of the package.

- Type of winding:Coil

- Dimensions, mm, d*D*h:400х650х200

- Weight kg:120 - 150

- Diameter range, mm:1,4 – 3,6

Each coil is tied with a metal steel tape (0.5x16) mm in at least six places evenly spaced around the coil. The coils are packed in a polypropylene cloth, tied around the circumference with tape and installed on wooden pallets of 2 coils (fixed to the pallet with packing tape (0.5x16) mm) or 3 windings (fixed to the pallet with metal tape (0.8x30) mm) in four places evenly spaced around the circumference. Pallet size is (730x730) mm. The pallet is lined with wrapping paper (cardboard). When packing 3 coils on a pallet, a wooden cross is installed inside the coils. At the request of the consumer, the coils can be packed in waxed paper and polypropylene fabric.

- Type of winding:Coil Z2

- Dimensions, mm, d*D*h:356x700x300

- Weight kg:350 - 450

- Diameter range, mm:0,5 – 2,5

Each coil is tied with a steel metal tape (0.6x19) mm in at least six places evenly spaced around the coil. Tapes are fixed with heat-treated wire Ø1.8 mm around the coil. The wire is lubricated with industrial oil, packaged in a polypropylene fabric. The canvas is fixed with tape. At the request of the consumer it is not lubricated or packaged.

- Type of winding:Bundle

- Dimensions, mm, d*D*h:400х800х500

- Weight kg:500 - 900

- Diameter range, mm:2,3 – 5,0

Coils are made on cardboard sleeves. The binding of the coils is carried out together with a cardboard shell with a metal tape (0.8x30) mm in four places evenly spaced around the coil with a grasp of the corners of the fabric. Rings are hung on the rosette. Rosette coils are packed in a stretch film (6 - 8) layers around the circumference. At the request of the consumer, shipment on wooden pallets (730x730) mm is possible.

- Type of winding:Coil «Rosette»

- Dimensions, mm, d*D*h:440х800х500

- Weight kg:500 - 600

- Diameter range, mm:1,6 – 2,5

Coils are made on cardboard sleeves. The binding of the coils is carried out together with a cardboard shell with a metal tape (0.8x30) mm in four places evenly spaced around the coil with a grasp of the corners of the fabric. Rings are hung on the rosette. Rosette coils are packed in a stretch film (6 - 8) layers around the circumference. At the request of the consumer, shipment on wooden pallets (730x730) mm is possible.

- Type of winding:Coil «Rosette»

- Dimensions, mm, d*D*h:440х800х800

- Weight kg:700 -800

- Diameter range, mm:1,6 – 2,5

Each bundle is tied with a steel metal tape (0.8x30) mm in four places evenly spaced around the circumference of the bundle. Each bundle is equipped with four load-lifting rings.

- Type of winding:Bundle К-2

- Dimensions, mm, d*D*h:500х850х650

- Weight kg:1000-2000

- Diameter range, mm:5,0-8,0